Services Offered by SHORES M.D.S.

Overview

We specialize in advanced measure and sketch piping services, tailored to meet the diverse needs of our clients in various industries. We offer a comprehensive range of services, from minor utility piping replacements to large-scale projects such as overhead piping replacements on FCC reactors. Our design capabilities encompass everything from simple reroutes to complex new pipe systems integrated within existing units.

Our Mission

Our goal is to eliminate rework in piping projects, achieving this through meticulously followed processes that ensure accuracy and efficiency.

Why Choose SHORES M.D.S.

- Reputation for Excellence: Since our inception, we have earned a reputation for delivering high-quality, affordable products that provide significant financial savings.

- Enhanced Safety: We are committed to safety by seeking to eliminate at-risk behaviors common in traditional measurement methods, such as working at heights, accessing hot surfaces, and packing multiple technicians for manual measuring tasks.

- Cost Efficiency:

- No scaffolding is required for measurements, drastically reducing time and labor costs.

- Only minimal insulation removal is necessary, which enhances safety and speed.

- Field welds are eliminated, streamlining the installation process.

- Overall, our service is more cost-effective than traditional scaffold building.

- "Field Verifiers": Unlike many design houses that require further validation after laser scanning, we take the extra step to verify field conditions ourselves, ensuring that our isometrics are accurate and reliable.

How We Work

- Advanced Measurement Technology: Our team utilizes a Leica robotic total station combined with automet™ software to gather only the necessary data efficiently.

- Self-Sufficient Operations: A single technician operates the equipment, leveraging either a survey prism or the instrument's reflectorless capabilities to gather data without the need for additional personnel.

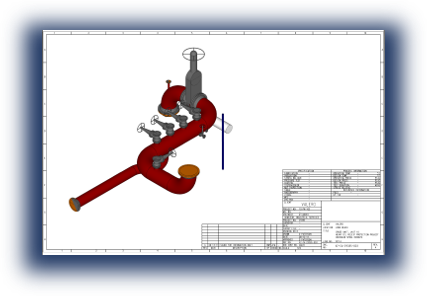

- 3D Modeling: Prior to leaving the site, our technician can construct a 3D model of the piping to be replaced, enabling us to visualize and better plan the upcoming project.

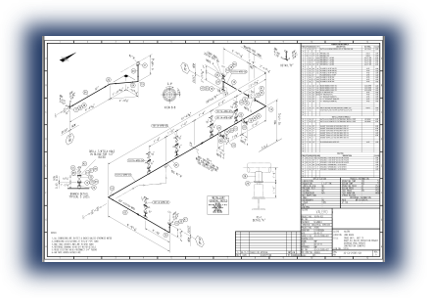

- Isometric Generation: Once data collection and processing are complete, accurate isometric drawings are generated and promptly shared with clients for fabrication, ensuring a smooth transition to installation.

Conclusion

Choose SHORES M.D.S. for your piping measurement and design needs, and experience a significant reduction in costs and an increase in safety and efficiency. Our innovative approach and commitment to quality make us a trusted partner in delivering piping solutions tailored to your specific requirements. If we can see it, we can measure it—streamlining your projects every step of the way.