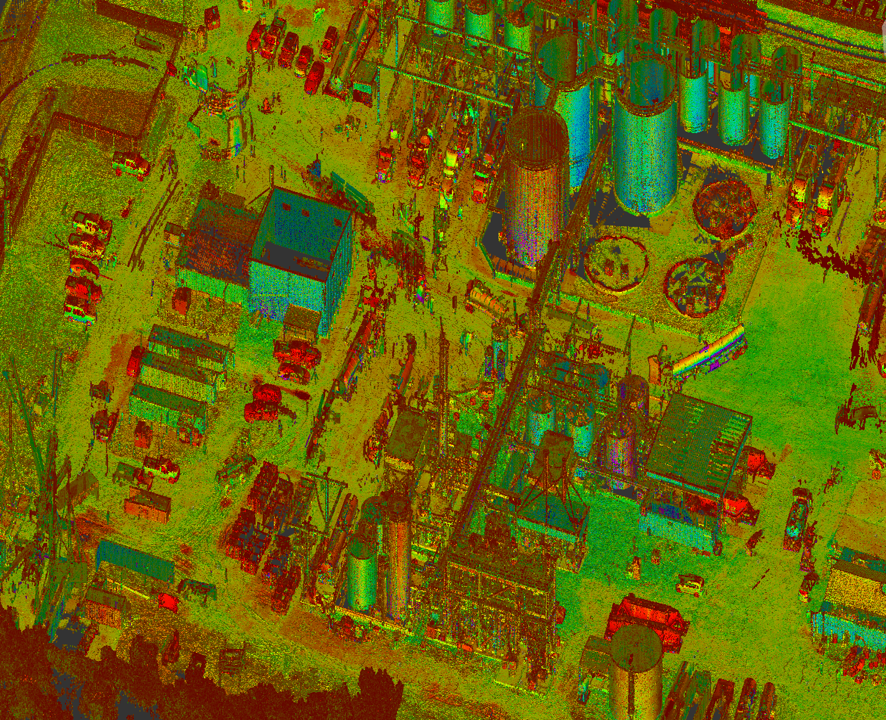

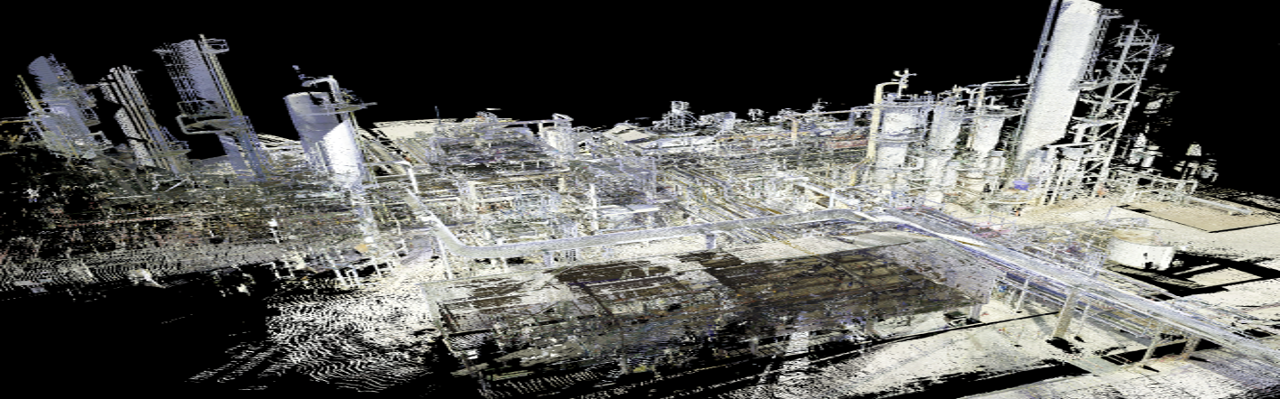

Full unit scanning is an essential practice in modern industrial processes, enabling comprehensive data capture within the defined boundaries or battery limits of a process unit. This technique can vary significantly in detail, from general overviews to intricate scans that support detailed design efforts.

Overall, full unit scanning is a powerful tool that enhances operational efficiency, fosters collaboration, and enables effective planning in complex industrial environments. By leveraging this technology, organizations can significantly improve their turnaround strategies and maintenance projects, ultimately leading to better productivity and reduced costs.

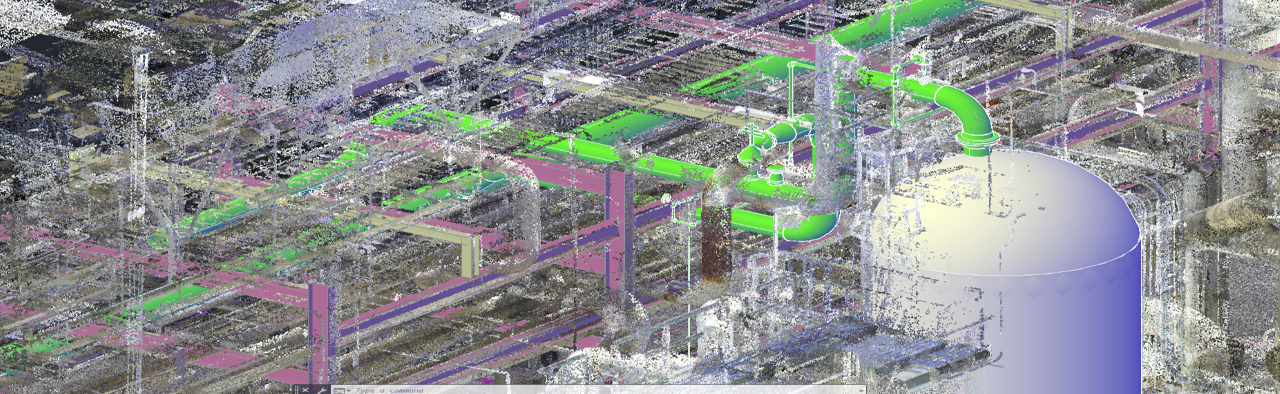

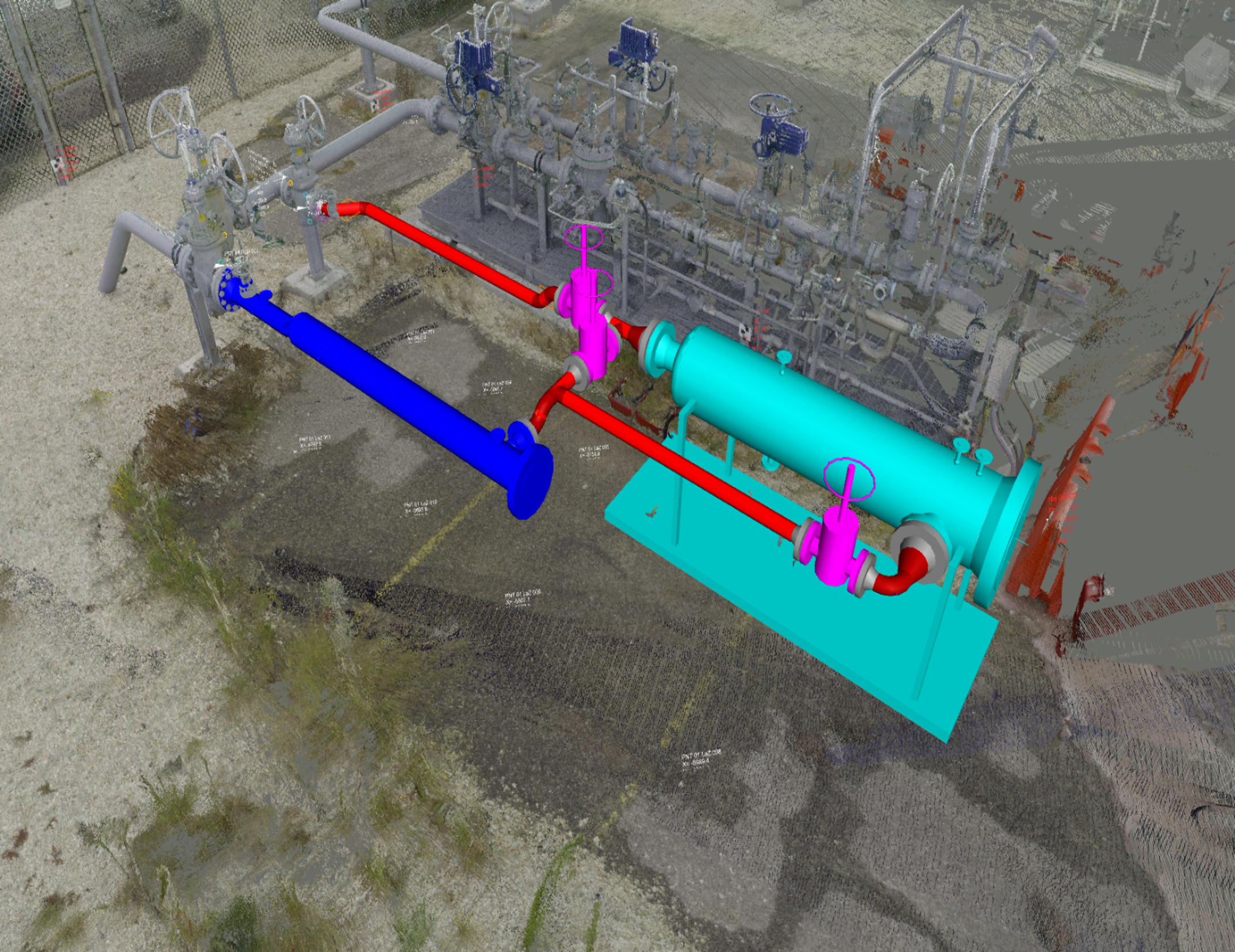

The advent of laser scanning technology has significantly transformed the pipe design process, addressing many challenges faced by designers in the field. Traditional methods often involved extensive time and labor, with designers physically verifying existing piping or conceptual routing in various environments, particularly in elevated or hard-to-reach areas. Laser scanning has emerged as a valuable solution, facilitating more efficient and precise design workflows. The technology has revolutionized pipe route verification by providing a fast, accurate, and efficient method for capturing existing conditions. It enhances the design process while mitigating risks and improving communication with clients. As a result, organizations can achieve more reliable and effective pipe designs, ultimately leading to greater project success and client satisfaction.

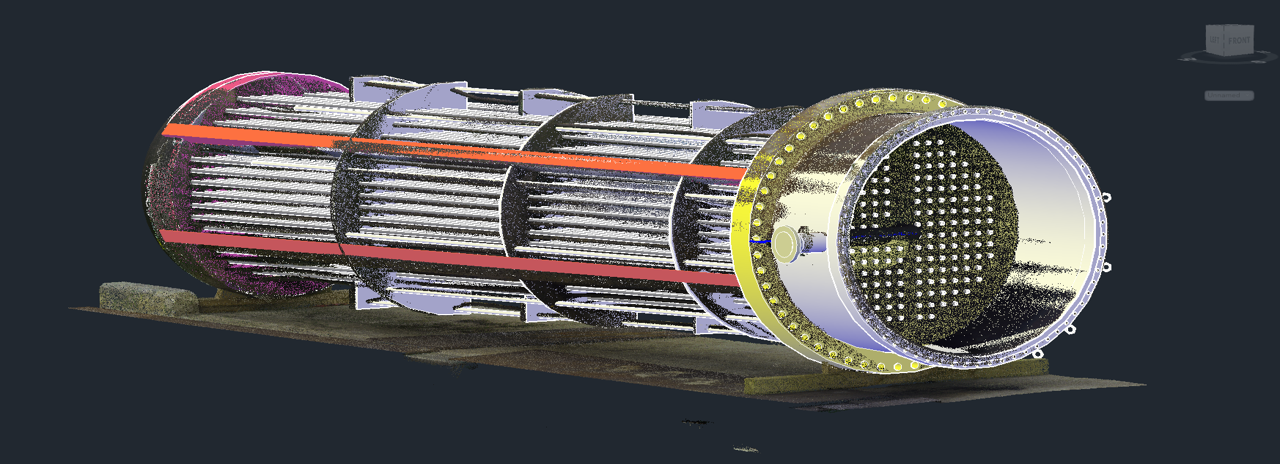

The SHORES M.D.S. Laser Scanning Group has been at the forefront of utilizing advanced laser scanning technology to support new design initiatives and the re-engineering of older equipment. This approach is particularly valuable in situations where detailed dimensional information about existing components is sparse or nonexistent, which can often hinder the fabrication process. Equipment scans using laser technology represent a transformative approach to the design and re-engineering processes. By capturing precise data quickly and integrating it with modern design tools, SHORES M.D.S. Laser Scanning Group enhances the efficacy of fabrication projects, reduces risks associated with redesigns, and strengthens client relationships through improved visualization and communication. This methodology stands as a testament to the power of modern technology in optimizing industrial operations.

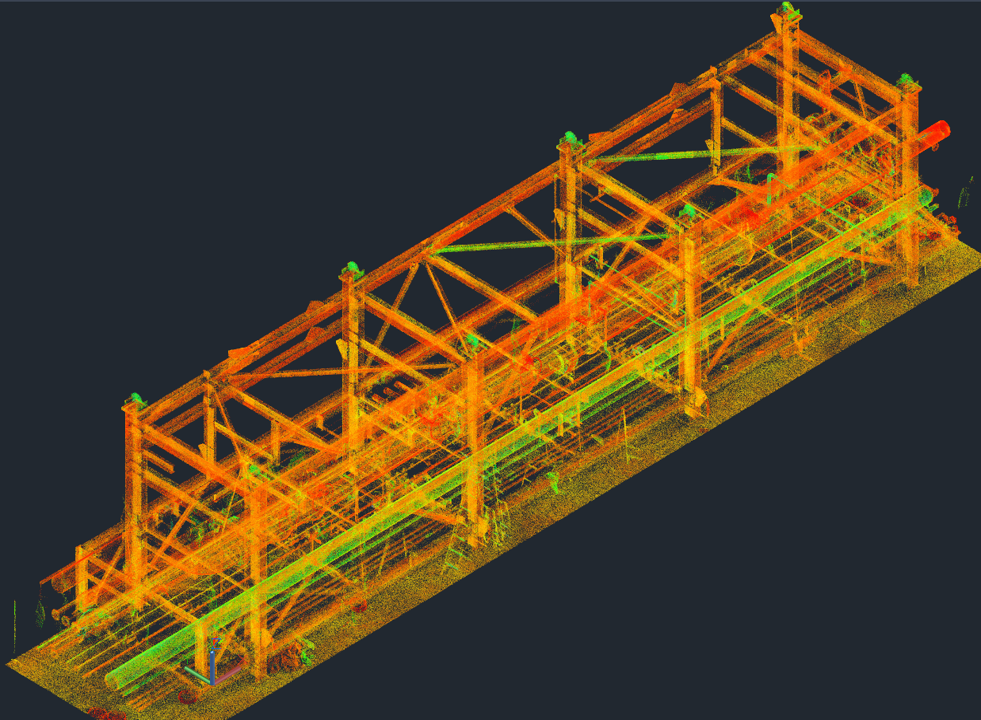

Module verification plays a critical role in the fabrication process, ensuring that all components meet the specified design constraints before they are transported and installed. Module verification is an indispensable part of the fabrication process at Shores. By utilizing precise laser scanning technology and thorough analysis, we ensure that every piping module meets the defined design constraints and coordinate specifications. This meticulous approach not only enhances the integrity of the final installation but also reinforces our commitment to quality and client satisfaction. As a result, our clients can move forward with confidence, knowing that their modules are ready for successful integration into their projects.